GET WHAT YOU PAY FOR

All of us are familiar with the old maxim that “you get what you pay for,” and most will readily vouch for that statement’s fundamental truthfulness. But when it comes to single-ply roofing membranes are building owners really getting what they pay for? Most are not and they aren’t even aware of it.

WHAT IS SIKA SARNAFIL'S THICKNESS GUARANTEE?

We guarantee that any Sarnafil branded membrane is produced at or above the labelled thickness for no extra cost and no long lead times to produce. And if the membrane does not measure up, we will pay up! It is that simple.

All Sarnafil branded (stock or custom) membranes are made above and beyond the ASTM standard when all others are giving you less and telling you their membrane is as good as a Sarnafil membrane.

WHAT DOES THE INDUSTRY ALLOW FOR PRODUCTION THICKNESS?

The American Society for Testing Materials (ASTM) developed a test for membrane thickness before the 2000’s when membrane production equipment didn’t have the ability to be perfectly accurate. Because of this, the standard allowed the membranes to be produced with a plus or minus 10% allowance, meaning that a membrane labeled 60 mils could actually be 54 mils and still be in compliance. Fast forward 20-30 years after the standard was developed and it is still being used while production equipment accuracy has improved greatly and can easily make a membrane the labelled thickness without much variance. Specifiers and building owners are generally unaware of this situation, even though it has a direct impact on product value and performance.

ROOFING MEMBRANE THICKNESS KEY DETERMINANT TO LONGEVITY

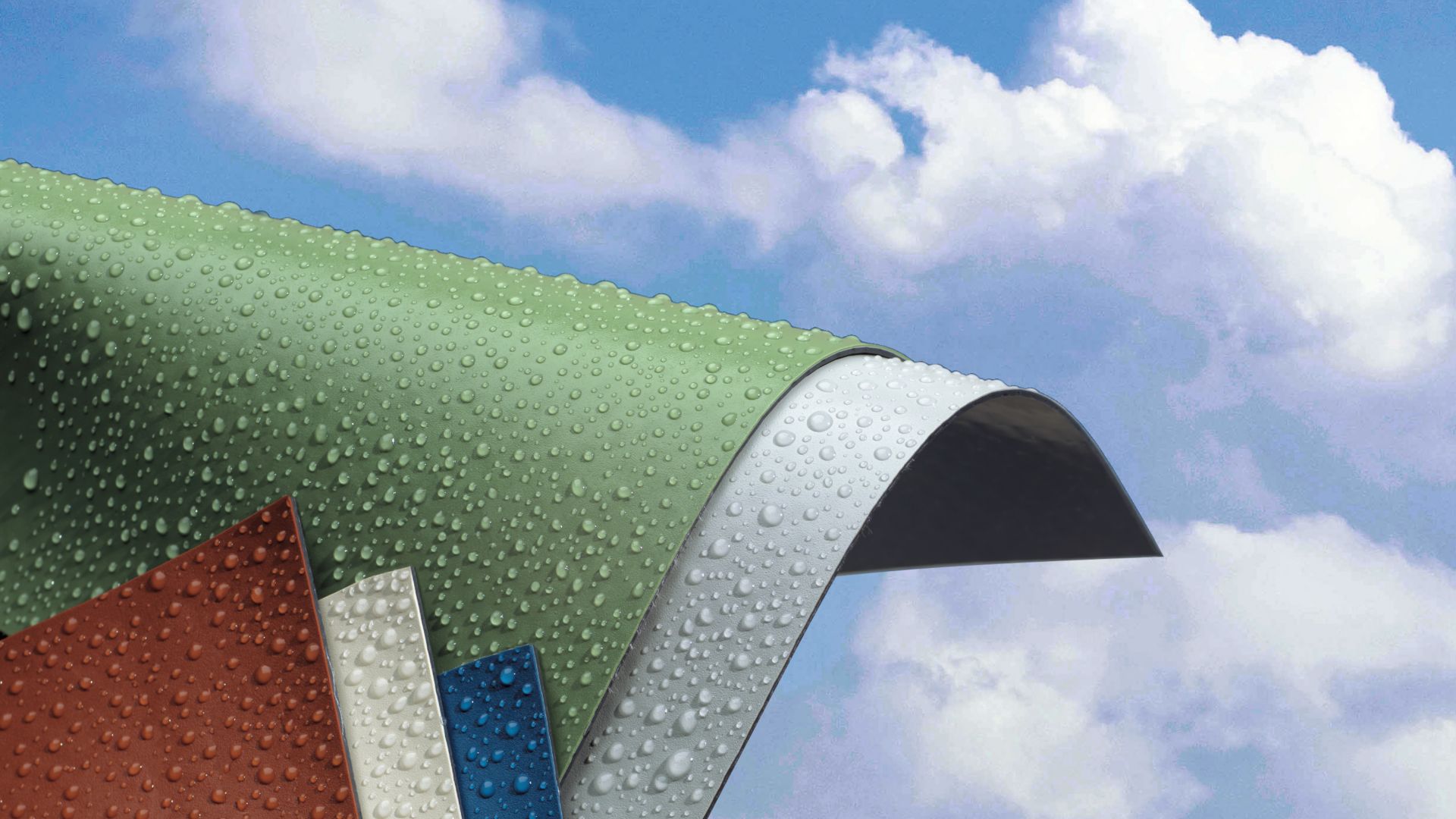

Roofing membrane thickness is a key determinant to longevity, durability and weldability. Roof surfaces have to withstand challenging climatic and meteorological conditions involving moisture, temperature, and solar radiation and wind. Over time, these forces combine to age membranes, resulting in part in a loss of thickness for all products. All other factors being equal, a thicker membrane withstands these forces longer.

In addition, commercial roofs typically host HVAC and mechanical equipment which entail foot traffic for maintenance and repair. Thicker membranes stand up better to punctures and abrasion, in addition to weathering and to aging. The commercial roofing market has generally moved in the direction of thicker membranes as a result. Read more on why a thicker membrane is better in the infographic below:

WHY THICKNESS MATTERS

Did you know that roofing industry standards allow a manufacture to produce a roofing membrane 10% thinner than its labeled thickness and still be in compliance? This infographic explores the importance of Why Thickness Matters, especially in a Roofing Membrane.

WHY ARE CUSTOMERS BEING SHORT CHANGED?

As mentioned above, production techniques utilized in the manufacture of single-ply membranes have advanced over the years and most major manufacturers can now produce membrane thicknesses with great precision. So why do so few companies produce single-ply membranes that actually meet the labeled thickness? For starters, the ASTM standards do not require it, but the primary factor is presumably the price-sensitive, competitive nature of the roof manufacturing business. One independent roofing consultant has estimated that the cost to add thickness to membranes is between $.01 and $.015 per sq ft per added mil of thickness. On a nominal 60-mil membrane, the added cost for just 3 mils (5 percent of 60) would be $.05 per sq ft. On a 1,000 sq.ft. job that increases the cost by $50,000 so you can imagine what the added cost is on larger jobs.

ARE MANUFACTURER'S REALLY PRODUCING THINNER MEMBRANES?

Independent testing of fifteen thermoplastic roof membranes by the consulting engineering firm Simpson Gumpertz & Heger in 1998 showed that only the Sarnafil-branded adhered and mechanically-attached membranes and one other membrane from another manufacturer actually met the labeled thickness, with all the other membranes failing to measure up. See table below:

Labeled vs. Measured Thickness Simpson Gumpertz & Heger, Inc. 1998

| Product | Labeled Thickness | Measured Thickness | Deviation of Thickness from Label | Deviation of Thickness from Label (%) | |

| Sarnafil S327 | 48 Mils | 48 Mils | - | - | |

| Sarnafil G410 | 48 Mils | 49 Mils | + 1 Mils | 2.1% More | |

| PVC 3 | 50 Mils | 40 Mils | - 10 Mils | 20.0% Less | |

| PVC 4 | 50 Mils | 44 Mils | - 6 Mils | 12.0% Less | |

| PVC 5 | 40 Mils | 34 Mils | - 6 Mils | 15.0% Less | |

| PVC 6 | 48 Mils | 43 Mils | - 5 Mils | 10.4% Less | |

| TPO 1 | 45 Mils | 43 Mils | - 2 Mils | 4.4% Less | |

| PVC 7 | 50 Mils | 46 Mils | - 4 Mils | 8.0% Less | |

| PVC 8 | 48 Mils | 40 Mils | - 8 Mils | 16.6% Less | |

| PVC 9 | 35 Mils | 28 Mils | - 7 Mils | 20.0% Less | |

| TPO 2 | 45 Mils | 43 Mils | - 2 Mils | 4.4% Less | |

| PVC 10 | 36 Mils | 33 Mils | - 3 Mils | 8.3% Less | |

| TPO 3 | 45 Mils | 42 Mils | - 3 Mils | 6.6% Less | |

| TPO 4 | 45 Mils | 46 Mils | + 1 Mils | 2.2% More | |

| TPO 5 | 45 Mils | 31 Mils | - 14 Mils | 31.1% Less |

Testing conducted by Sika Sarnafil over 20 years later in 2013, and involving most of these very same single-ply membranes, showed that nothing had changed. These test results indicate that virtually all manufacturers other than Sika Sarnafil produce membranes at or near the bottom of the 10 percent ASTM tolerance in thickness See table results below:

HOW TO GET APPLES TO APPLES BIDDING

In bid situations, competitive membranes may be labeled 48 mil or 60 mil, but in reality only one is likely to actually meet the mil thickness — Sarnafil. But architects and/or consultants can fix this by specifying a minimum thickness rather than a nominal thickness in competitive bid situations, all manufacturers would be forced to supply the same minimum thickness. This program also heightens both the awareness and the importance of fair product comparisons. A minimum membrane thickness requirement establishes a more uniform basis for comparison when multiple manufacturers compete in a bid situation, and all specified products would be required to meet the same membrane thickness criteria.

WE'LL MEASURE UP, OR WE'LL PAY UP

Sika Sarnafil has a no-nonsense reputation for delivering roofing solutions that withstand the world’s harshest conditions. The Thickness Guarantee Program for Sarnafil membranes ensures that architects and roofing consultants can specify with confidence, and that building owners will truly “get what they pay for.” Roofing contractors can continue to look to Sika Sarnafil as a trusted partner in giving their customers the longest lasting thermoplastic roof.

Sika guarantees that the thickness of any Sarnafil membrane* will meet or exceed the thickness indicated on the package label. If, at the time of installation, the membrane measures less than the labeled thickness per ASTM D-751, Sika will remunerate the building owner $0.05 per square foot for the amount of material measuring less than the labeled thickness to a maximum of $5,000.

Sarnafil roofing and waterproofing membranes are manufactured with a thickness ranging from 48 mils to 96 mils. Applicable products include all Sarnafil-branded membranes in all widths, including flashing membrane. This would encompass all thicknesses of Sarnafil S 327 and G 410 roofing membranes as well as the company’s G 476 waterproofing membrane. The membrane thickness in mil units is included in the descriptor on the membrane roll labels for all Sarnafil-brand membranes.

For feltback membranes, lamination of felt to the back of the membrane interferes with the measurement of the membrane thickness after manufacture. Verification of membrane thickness will be made based on manufacturing quality assurance data.