2019

Nunavik Territory, Québec

PROJECT DESCRIPTION

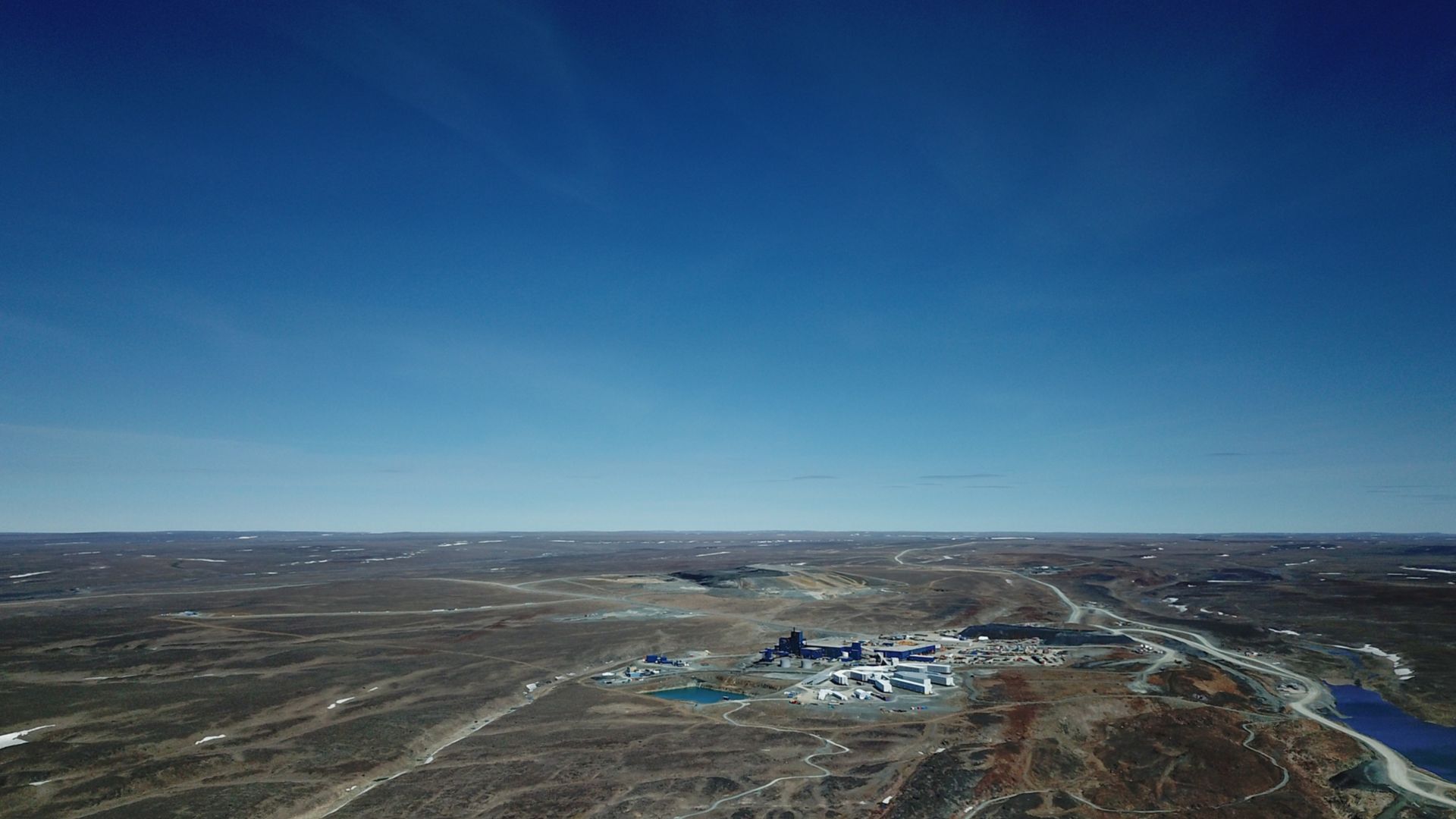

The Glencore Raglan mine, is amongst the richest Ni-Cu-PGM mines globally. The mine is located in permafrost ground in the Nunavik Territory, Québec, in proximity to the village of Salluit, a community on the Arctic coast. We have been involved with this underground mining project since the day the project broke ground in 1998 by Falconbridge Limited. King designed and supplied a special shotcrete mix, the MS-D3 Raglan, to meet their stringent conditions. The Raglan mine continues to use this product to date. The mine site’s extreme, remote location and climatic conditions allow for limited sealifts per year and the arctic weather conditions are among the harshest globally. The average annual temperature in the region is -10 °C. Approximately 650 mm of precipitation falls annually of which 75 % is in the form of snow. Lake and river ice breaks-up in early July and freezes in late September to early October. This time window is critical for the supply logistics to the site. Currently there are 4 underground operations active at the Raglan camp which supply 1.3 million tonnes of ore to the Raglan concentrator. The Raglan Ni-Cu-PGE sulphide deposits in the Cape Smith Belt, where the Raglan mine is located, are associated with ultramafic intrusions. These intrusions host the sulphide deposits of Raglan which are typically comprised of clusters of multiple distinct lenses that are extracted using cut and fill mining as well as long hole stoping.

BUILDING A MINE UNDER EXTREME CLIMATIC CONDITIONS

For general underground rock support purposes, a ready-bagged Sika-King dry-mix shotcrete is used frequently at the site and has proven to be a robust shotcrete system considering the logistics to the site and the limitations of batching wet-mix shotcrete at Raglan. The shotcrete is applied using robust and reliable Sika® Aliva® rotary equipment. In order to allow efficient underground development at Raglan, a shotcrete needed to be designed that allows rapid hardening even in a very low temperature environment. The main goal was to develop a shotcrete mix that would set and harden in very cold conditions when applied on permafrost. In order to achieve the objective, it was important that the mix would rapidly generate high heat of hydration once sprayed. This shotcrete system has proven very effective over the years.

SUSTAINABLE MINE DEVELOPMENT

Sustainable development has always been of great value to Glencore and Raglan mine and replacing part of it’s diesel consumption with a clean and renewable source of energy, is an important step toward reducing the mine’s ecological footprint. In 2014, with the collaboration of key players such as Tugliq Énergie, a Québec society of renewable energy, and Enercon, a German wind turbine manufacturer and engineering firm and Raglan Mine, reached its goal and inaugurated its first wind turbine.

The second wind turbine was installed recently. Construction phases were challenging due to Nunavik’s permafrost and it’s rigorous, yet extremely windy climate. Inorder to reach a solid rock base, the first wind turbine’s platform was installed on twelve (12), circular, 0.4 meter in diameter, 16 meter in length, bored piles, containing an on-site fabricatedrebar cage. The second wind turbine piles were installed at a 24 meter depth, where solid rock was found.

SIKA-KING SOLUTIONS

After dropping in the rebar cages, each pile of the second wind turbine was filled with a specialized King grout for permafrost conditions, called “Nordic”. The wind turbine’s base had to be aligned and mounted over the twelve piles by means of a complex anchoring system. Each pile possessed a larger diameter on the superior portion which was designed to be filled with high-performance concrete to withstand the cold temperature and reach sufficient compressive strength atan early age, to allow Raglan’s crew to begin the structure erection and deliver the project on time. For this critical concrete pour, Raglan chose King® HP-S10 80, a custom made 80 MPa concrete mix in order to fix the anchor points.

A King technical representative was on-site to ensure proper concrete mixing and placement and to conduct quality control testing on the redundant material. Concrete samples were taken from every concrete truck, in order to determine the concrete’s compressive strength by an external laboratory. A 4 m3 capacity, concrete mixing truck was used to mix and pour the King® HP-S10 80. Water dosage was controlled on-site in order to obtain theproper consistency without exceeding the recommended quantity of water. Although the in situ temperature was close to the freezing point, King® HP-S10 80 fully cured and was sufficiently resistant to begin the wind turbine assembly after only seven (7) days.

CABLE BOLTING IN PERMAFROST

Underground mining in very cold climates, including many of the world's arctic regions, is becoming more and more common. Furthermore, automated rock support installation has become a main driver for increasing efficiency during underground development.With this new era, several technical challenges have emerged with a greater emphasis on products and their performance under such harsh climatic conditions.

The grouted portion of the cable bolt system is critical to the success of the cable installation and to ensure proper ground support. Normal Portland based cement will not properly hydrate in temperatures below the freezing point. King has developed a grout technology that has been adapted for several permafrost grouting applications, including grout for pile construction of surface infrastructure, fluid consistency neat grout for cable-bolting, using the breather tube method and a thick consistency neat grout for automated cable bolters using the grout and insert method.

REQUIREMENTS

- Efficient grouting, reaching specified strengths in permafrost and general arctic, climate conditions

- Sufficient fluidity for a certain period of time to allow pumping and placement, but must set quickly to generate enough heat in order to avoid freezing, which would permanently damage the grout

- Easy to handle packaging and dosage of materials

- Conistency that allows above head grouting application (thixotropic behaviour)́

- In cycle, high performance shotcreting in arctic environment

- Reliable application of products when needed

- Equipment support for shotcrete

- Ongoing technical site support

- Full compliance with the mines logistical and storage requirements

PRODUCTS USED ON THIS PROJECT

*please note that the nordic cable linked here is the classic product, the nordic cable used on this project is a special mix (TC). Contact your Sika-King technical sales representative to inquire about the product.

** contact your Sika-King technical sales representative concerning Aliva equipment.